Petro-King Turbo FZCO has advanced the evolution of

high speed turbo drill motors through dedication to all aspects of high speed turbo drill motors design.

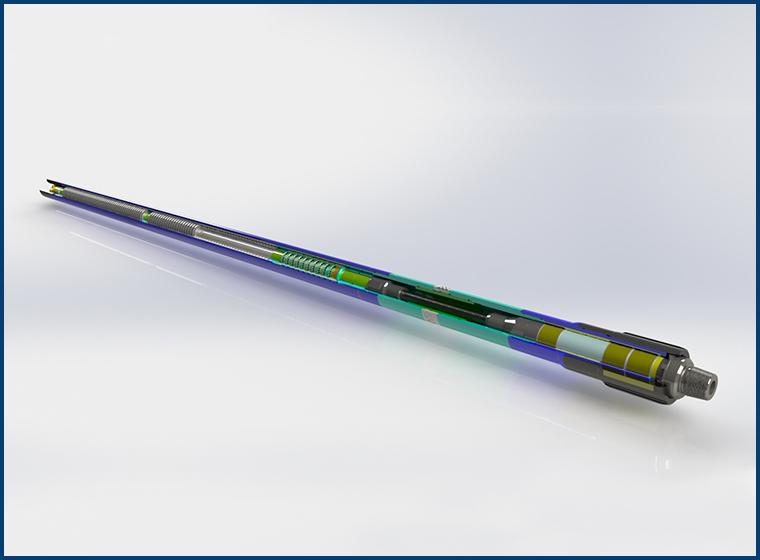

A high speed turbo drill motors consists of multistage vane-type stator and rotor blades which converts the hydraulic energy (flow x pressure) of the drilling fluid into mechanical energy to drive a shaft and drill bit. A “stage” consists of one set of stator and rotor blades. The stators are stationary, locked to the turbine body, and deflect the flow of drilling fluid onto the rotors which are locked to the drive shaft. As the rotors are forced to turn, the drive shaft is also forced to turn, causing the bit to rotate.

The high RPM and durability of the high speed turbo drill motors lends itself well to hard rock drilling applications with impregnated diamond bits where the capability to remain in the hole for extended periods is economically advantageous. The ability to configure the tool with no elastomer components allows the turbodrill to be utilized in extreme environments including HPHT, geothermal and UBD.

In specific applications the high speed turbo drill motors high power output provides a superior drive system for performance drilling with PDC bits. The combination of high RPM and relatively low torque together with the smooth concentric running of the high speed turbo drill motors allows for extremely accurate tool face control in directional applications.

Petro-King Turbo FZCO has advanced the evolution of high speed turbo drill motors through dedication to all aspects of turbodrill design.

All Petro-King Turbo FZCO high speed turbo drill motors are of single section design, as opposed to the conventional modular construction used by competitors. This provides several customer benefits:

- Reduced rig handling time & safety risk exposure

- Reduced overall length / bit to MWD/LWD distance

- Reduced threaded connections.

- Reduced freight costs.

A reduction in the length of the distance between the bit and bend on the High Speed Turbo Drill Motors has also been achieved. This increases the dogleg capability of the High Speed Turbo Drill Motors achieving the same doglegs with lower bend settings. Specifically targeting but not limited to short radius wells. The reduced bend to higher dogleg ratio on the tool means that there is less lateral stress on the tool in any given point reducing any additional lateral loading f the tool and therefor reducing the percentage possibility of downhole tool failure.

The performance of PKT-Turbo high speed turbo drill motors has been greatly enhanced through the utilization of highly advanced Computational Fluid Dynamic software which has been developed specifically for turbomachinery. This provides a full simulation not only of the fluid flow but also of the rotational dynamics of the blades. This has resulted in the optimization of blade design that has produced overall output characteristics which delivers:

- Increased torque & speed output

- Increased overall power

- Increased efficiency

- Reduced Blade quantity

HIGH SPEED TURBO DRILL MOTORS

Petro-King takes the lead in introducing the 800-1500 rpm high-speed high speed turbo drilling motors technology in China and formed a unique effective technology for fast drilling for igneous rock, gravel layer, highly-abrasive quartz sandstone, in combination with uniquely designed diamond impregnated bits.

Our tenets are: “Continuous Improvement” and “Implementation”